You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I did my own Dee and ricky

- Thread starter skidzz

- Start date

Bubbly Tubs

Moderator

Looking good there fella. Haven't got brave enough to pull any Gs apart yet. I've got one I want to change from pos to neg display but not really sure where to start.

macspite

Member

The LCD segments show by virtue of a thin sheet of polarising film over the module glass. Remove the film, replace with another bit of polarising film at right angles to the original and the display is reversed. Did my first yesterday:

Get a washing up bowl, a Phillips #000 screwdriver, some solvent and lint free cloths, a scalpel or craft knife and the film (PM me for stockist). Some silicone grease to reseal the back would be good. Pliers, springbar remover and a jewellers loupe (eyeglass) are helpful. I also find the bamboo barbeque skewers for making kebabs are a very useful tool.

Take the back off the watch working inside the washing up bowl so that the wee screws don't get lost when you drop them. You may need to remove the strap before you can remove the case back. It makes sense to take photos as you go to check how things go back. I used a DW-6600 to experiment on which is a fairly uncomplicated watch to play with, haven't tried a waveceptor or tough solar - yet.

There is no need to take the battery out, just remove the rubber "mat" and the module is exposed. There is a tiny coil spring that stands up from the module, best to gently remove it and put it in the bottom of the washing up bowl rather than wait for it to escape on its own.

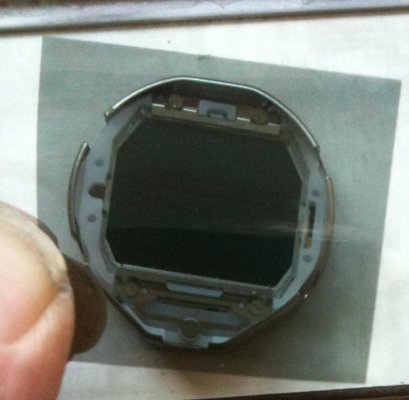

Lift out the module from the case and turn it over.

disassembled DW-6600

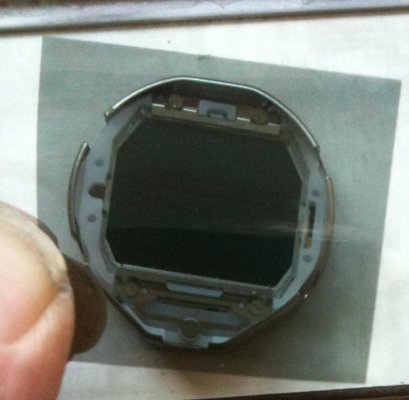

Now comes the brutal bit - remove the polarising film by inserting the point of the knife between it and the glass of the LCD. The film is stuck to the glass but will come away as you move the knife blade around the face.

knife between film and glass

Then, if necessary, grip the film with a pair of pliers and gently peel away from the module glass

The glass will have some residual cement on it.

I used a solvent cleaner from RS, a lint free cloth and the point of a bamboo skewer for the difficult bits to get rid of the cement.

Next you cut the new polarising film to size. You can buy either self adhesive film and trim accurately to fit over the LCD cover glass or, as I did, use non adhesive film cut to fit into the space between module and watch crytal - less precison required in the cutting.

Check the orientation of the film - one way almost clear, turn through 90 degrees for negative effect:

As they say in Haynes' manuals "Assembly is the reverse of dis-assembly"

The O ring gasket could do with a smear of silicone grease to maintain waterproofing, don't forget the tiny spring need to go back else there will be no alarm and hour signals. And this is what you end up with:

Get a washing up bowl, a Phillips #000 screwdriver, some solvent and lint free cloths, a scalpel or craft knife and the film (PM me for stockist). Some silicone grease to reseal the back would be good. Pliers, springbar remover and a jewellers loupe (eyeglass) are helpful. I also find the bamboo barbeque skewers for making kebabs are a very useful tool.

Take the back off the watch working inside the washing up bowl so that the wee screws don't get lost when you drop them. You may need to remove the strap before you can remove the case back. It makes sense to take photos as you go to check how things go back. I used a DW-6600 to experiment on which is a fairly uncomplicated watch to play with, haven't tried a waveceptor or tough solar - yet.

There is no need to take the battery out, just remove the rubber "mat" and the module is exposed. There is a tiny coil spring that stands up from the module, best to gently remove it and put it in the bottom of the washing up bowl rather than wait for it to escape on its own.

Lift out the module from the case and turn it over.

disassembled DW-6600

Now comes the brutal bit - remove the polarising film by inserting the point of the knife between it and the glass of the LCD. The film is stuck to the glass but will come away as you move the knife blade around the face.

knife between film and glass

Then, if necessary, grip the film with a pair of pliers and gently peel away from the module glass

The glass will have some residual cement on it.

I used a solvent cleaner from RS, a lint free cloth and the point of a bamboo skewer for the difficult bits to get rid of the cement.

Next you cut the new polarising film to size. You can buy either self adhesive film and trim accurately to fit over the LCD cover glass or, as I did, use non adhesive film cut to fit into the space between module and watch crytal - less precison required in the cutting.

Check the orientation of the film - one way almost clear, turn through 90 degrees for negative effect:

As they say in Haynes' manuals "Assembly is the reverse of dis-assembly"

The O ring gasket could do with a smear of silicone grease to maintain waterproofing, don't forget the tiny spring need to go back else there will be no alarm and hour signals. And this is what you end up with:

Bubbly Tubs

Moderator

That is an awesome little guide. Defo need to get some polarising film. Then that bad boy is coming apart ha ha

seanobsdot

New Member

this is really amazing maybe we can get a tutorial on the ga110s. are they harder to take apart and such? anysqays good job on the watches you should start a customization business. i know people that would pay for this.